|

As the exhaust steam travels from the cylinders and through the smokebox to the chimney, it creates a draught which draws the smoke and gases from the firebox and boiler tubes and also pulls fresh air through the firegrate. The harder the engine is worked, the more steam is used, which in turn means a bigger draught and a hotter fire that leads to faster steam production.

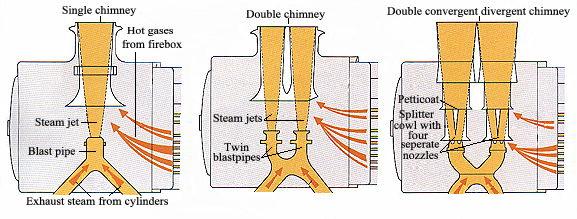

The used steam from the cylinders is ejected from the blastpipe, which is a nozzle at the bottom of the smokebox facing the chimney mouth.

Up to a point, the smaller the nozzle the greater the speed of the steam and the stronger the draught, however, this creates a draught that is uneven and tends to draw out pieces of half-burned coal with the smoke from the fire. In addition, a small nozzle creates back pressure in the cylinder because the used steam cannot escape fast enough. An ideal blast is strong but slow and steady, and provides a fast passage for the steam leaving the cylinders.

Because the strength of the draught through the firebox and boiler tubes is directly related to both the used steam velocity and the total area of the steam jet in contact with the gases in the smokebox, it is possible to improve the draught by altering the design of the nozzle in the blastpipe.

The simplest and easiest method to improve draughting is to have two blastpipes, each exhausting through a different orifice in a double chimney. This design was favoured by the L.M.S. Railway where it produced a startling improvement in the performance of the Royal Scot class of locomotives. Similarly, after nationalisation, this design was applied to the GWR King and Castle classes with equally noticeable improvements.

Probably the most advanced method of draught improvement was with the Kylchap design, perfected by the French engineer Andre Chapelon. This had two blastpipes, but each nozzle formed a cross-section of four circles joining in the centre, so that the steam emerged as four jets that met in the middle. Beneath each chimney orifice were two petticoat pipes, shaped to split the four jets and then combine them again as a single jet that was exhausted through the chimney.

Locomotives that were fitted with the Kylchap exhausts were noted for their exceptionally free running. The exhaust from the chimney was so soft that non-streamlined engines required deflector plates to lift the smoke away from cab windows.

|