|

|

|

Back to basics

Section 11 - Tyres and profiles

|

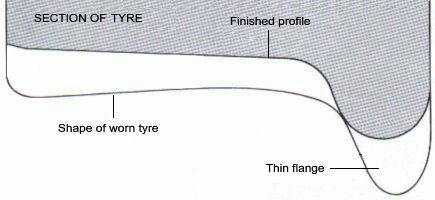

The earliest form of railways used wooden spoked wheels surrounded by a flat plain metal rim or tyre that ran on an angled rail. These tyres would rapidly wear out until the design was altered so that the flange was fitted to the tyre instead of the rail. Various cone shaped tyre profiles were tried by the different railway companies and these studies showed that bogies with wheels that had a steep cone-shaped profile wobbled severely as the wheel tried to centre itself after leaving a sweeping curve or a set of points. If the movement was severe enough that the wheel flanges repeatedly grazed against the railhead, this movement was called hunting. In addition to causing excessive tyre and rail wear, it would also give a rough ride. Eventually the findings of the trials led to the use of cone-shaped tyres of a less steep profile and all English and Scottish railway companies agreed to standardise their wheel profiles. |

Copyright © by John Daniel 2013.