|

|

|

Back to basics

Part 5 - Valve and piston layout and movement

Position the mouse cursor over part of the image below to find its name and function

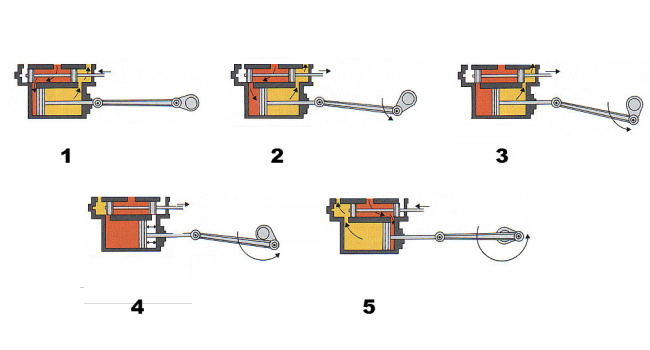

The valve head is ahead of the front port, allowing steam under pressure into the cylinder to push the piston back

As the piston begins to move backwards, used steam from the previous stroke is exhausted through the rear port

After almost half of the pistons full stroke, the valve head cuts off the steam supply. The steam continues to expand and pushes the piston back

The front port begins to open ready to exhaust the used steam. The rear port is closed creating back-pressure before the next stroke begins

Fresh steam enters the rear port and the process begins again

|

Tto ensure the efficient working of a steam locomotive, steam has to be admitted to, and exhausted from the cylinders at the precise moment in the pistons cycle. This is achieved by valves located next to each cylinder. |

Copyright © by John Daniel 2013.