|

|

|

Back to basics

Section 10 - Superheating

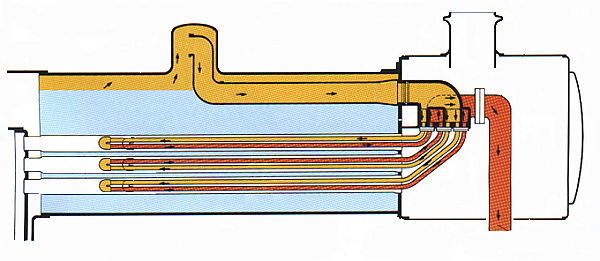

Position the mouse cursor over part of the image below to find its name and function

Boiler barrel

Water level inside the boiler

Rear tube plate - rear mounting for the tubes

Steam dome - highest point of the boiler and also usually contains the regulator valve

Main steam pipe - transfers steam from the regulator valve to the superheater header

Large flue tubes - contain the superheater elements

Superheater elements

Chimney

Steam pipe that carry the superheated steam to the cylinders

Superheater header - carries the saturated steam to the superheater elements and also the superheated steam to the steam pipe

Smokebox

Front tube plate - front mounting for the tubes

|

The introduction of superheating was the single most important development for the steam locomotive. Superheating increases the power output of a locomotive by up to 25%, with equivalent savings in coal and water, over non-superheated engines. Its widespread use from 1910 coincided with the needs from the railway operators for heavier trains to be hauled at higher speeds. |

Copyright © by John Daniel 2013.