|

|

|

The Severn Railway Tunnel.

Chapter 7 - Major Gains and Greater Troubles.

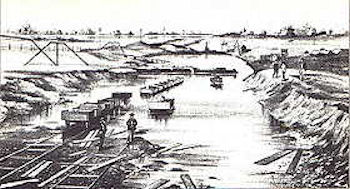

The first nine months of 1883 were very successful in the construction of the Severn Railway Tunnel. Where the ground had collapsed on the Gloucestershire side of the river in November 1882, this area of heading was secured and driven to the extreme eastern end of the tunnel. The huge cutting on this side advanced further by the use of two steam-navvies, but where a public road and a main drain crossed the cutting it was originally intended that a bridge would span the gap, but after the lowering of the tunnel, it was found necessary to use a short length of tunnel here instead of a bridge. A shaft was therefore sunk adjoining the cutting to construct this short tunnel.

Further sections of completed tunnel were finished, notably at the bottom of the 5 miles 4 chains, Marsh and Hill Shafts and the cutting on the Monmouthshire side of the river was begun in March. The hole which had been capped by clay in the Salmon Pool the previous year required further attention which culminated with a thick layer of concrete placed over the hole in 1884.

On the 9th of February, a reminder of the hazards of tunnelling affected all of the men at the works. At the end of the shift that worked from 3 o'clock p.m. until 1 o'clock a.m., a group of men who were returning to the surface gathered in one of the winding cages at the bottom of the 5 miles 4 chains Shaft. The other winding cage was at the surface bringing loaded skips to the clay crushing machine when John Nash the labourer in charge of the skips, in a moments lapse of concentration, pushed an empty skip over the edge of the shaft where the cage on that side was at the bottom with the returning miners. The skip fell about 140 feet and killed three men in the bottom cage before rebounding among a crowd of men standing nearby, killing another man and seriously injuring two others. John Nash was found not guilty, but to live with the accident on his conscience was like a life sentence in itself.

The works were in an advanced stage of construction at the end of May 1883 except for the 200 yards section around the Great Spring and so it was decided to open the door in the headwall that held back the spring. Unfortunately, a large quantity of debris had fallen down behind the door making it impossible to open. An area 12 inches across was then broken out of the door, releasing the water and soft material into the heading, until the access hole itself was blocked by rocks. These then had to be manually broken up through the access hole releasing more water until the next rock again blocked the hole. For two months the men continued to work in this fashion, but it was realised that little progress was being made by this method. Another heading was then driven under the Great Spring and then upwards to give access to the area behind the headwall. Inspection then showed that the roof had broken in for 50 or 60 feet leaving a cavern large enough to swallow a house, but fortunately with little water

emanating from the cavern. A large amount of work was required before this area was made safe and the heading continued.

In his six monthly report to the Great Western directors, Sir John Hawkshaw reported that nearly 1½ miles of tunnel was completed and an additional ¾ of a mile of top break-up had been brick lined, and the cuttings on the English and Welsh sides were on target. By early October through the optimism of a rapid completion of the tunnel was to be dashed.

On the 10th of October, the six o' clock evening shift had just started work after taking the skips from the Sudbrook shaft to the heading being driven under the area of the Great Spring. As the men began to shovel up the loose rock dislodged by blasting, water suddenly burst into the heading from its bottom face. It swept the men and the iron skips up and moved them from the bottom heading into the completed tunnel near the shaft. Gallantly the men tried to walk back into the heading to the close the door of the headwall, but were forced back by the power of the water.

Walker arrived at the works and on descending the shaft, found a river of water that fortunately tasted fresh indicating that the river had not broken in, but it was evident that the amount of water flooding into the works far exceeded the pumping power at Walker's disposal. The headings west of Sudbrook, that is from 5 miles 4 chains, Marsh and Hill Shafts were not connected to one another or the main workings running from Sudbrook under the river, however, the main tunnel could possibly flood onto the Gloucestershire side, and so a headwall was built across the finished tunnel just west of the Sea Wall Shaft.

Fortunately all of the men escaped from the tunnel, but three horses which had been temporarily stabled in the tunnel were drowned. The amount of water flowing into the works was estimated at 27,000 gallons per minute against the total pumping power in this section of 11,000 gallons per minute. By the following morning, the depth of water in the Old Shaft was 52 feet but the next day, the water was being held by the pumps at a depth of 132 feet. To add to Walker's problems though, the largest of the pumps at 5 miles 4 chains broke down and within a few hours that section was also flooded.

A council of war was held and concluded that the flooding in the main heading was from a subterranean reservoir which would soon exhaust itself and therefore it was decided to continue pumping for another two or three weeks, but also to contact Alexander Lambert, the diver who had closed the headwall door in the long heading wearing Fleuss' apparatus, so that he could close the headwall door under the Great Spring.

To add to the misery felt by all connected with the Severn Tunnel, the weather forecast for the 17th of October 1883 read:

South-West England and South Wales;

South westerly to westerly winds,

strong to gale force, squally, showery, changeable . . .

At 7 o'clock p.m., the night shift of 70 men at the Marsh Shaft were extending the 450 yards of tunnel so far completed with break-ups in two sections. The predicted storm was blowing fiercely but it was known that one of the highest tides of the year would occur that night. Between Marsh Shaft and the river, several small cottages housed men from the works. Then out of the darkness, there suddenly emerged a tidal-wave engulfing the land with a solid wall of water six feet high. As it swamped the cottages, the water rose above the beds of sleeping children but were plucked to safety and placed on high tables or shelves. When the tidal-wave reached the Marsh Shaft, it first extinguished the fires of the boilers for the winding and pumping engines and then poured into the 100 feet deep shaft. Immediately the men underground realised the danger and ran to the bottom of the shaft only to find the lift cage immobilised. Some men then tried to climb an iron ladder inside the shaft, but the cascade of water forced many of them back. Their only means of retreat was by going up the gradient of the tunnel to where a wooden platform had been built for installing the brick lining in the roof of the break-up, however, even here the water level got to within 8 feet of the roof. The foreman of the works arrived at the shaft and, assisted by two engineering staff and other men, together they rapidly built a dam at the top of the shaft from clothing, sacks and anything else that came to hand. A small boat was called for which had to be lowered on end into the shaft and a few men with lights climbed into the boat and began to paddle up the tunnel. They had not gone far when a large timber cross-piece used as a temporary support in the tunnel, blocked the path of the boat. Returning to the shaft, they obtained a saw and started to cut

away the timber. But such was the pressure on them, that their grip on the saw was lost and they had return to back to the shaft for another saw, however, in time, the boat collected all eighty-three men on the platform.

70 men at the Marsh Shaft were extending the 450 yards of tunnel so far completed with break-ups in two sections. The predicted storm was blowing fiercely but it was known that one of the highest tides of the year would occur that night. Between Marsh Shaft and the river, several small cottages housed men from the works. Then out of the darkness, there suddenly emerged a tidal-wave engulfing the land with a solid wall of water six feet high. As it swamped the cottages, the water rose above the beds of sleeping children but were plucked to safety and placed on high tables or shelves. When the tidal-wave reached the Marsh Shaft, it first extinguished the fires of the boilers for the winding and pumping engines and then poured into the 100 feet deep shaft. Immediately the men underground realised the danger and ran to the bottom of the shaft only to find the lift cage immobilised. Some men then tried to climb an iron ladder inside the shaft, but the cascade of water forced many of them back. Their only means of retreat was by going up the gradient of the tunnel to where a wooden platform had been built for installing the brick lining in the roof of the break-up, however, even here the water level got to within 8 feet of the roof. The foreman of the works arrived at the shaft and, assisted by two engineering staff and other men, together they rapidly built a dam at the top of the shaft from clothing, sacks and anything else that came to hand. A small boat was called for which had to be lowered on end into the shaft and a few men with lights climbed into the boat and began to paddle up the tunnel. They had not gone far when a large timber cross-piece used as a temporary support in the tunnel, blocked the path of the boat. Returning to the shaft, they obtained a saw and started to cut

away the timber. But such was the pressure on them, that their grip on the saw was lost and they had return to back to the shaft for another saw, however, in time, the boat collected all eighty-three men on the platform.

The tidal-wave not only flooded the area around the Marsh Shaft but also covered a great deal of the lowlands on both sides of the river. Many people commented that such a high tide had not been seen for a hundred years and yet this was the type of calamity that Charles Richardson had investigated when designing the tunnel complete with its necessary sea defences. Unfortunately, those defences above the Monmouthshire cutting had not been completed and the cutting was completely flooded however the heading down to the Hill Shaft was not connected so the flood never extended to that area.

On the morning of the 18th of October the Severn Tunnel works was in a worse condition than even when the Great Spring burst into the Old Shaft heading. The only areas where work could be continued was around the Hill Shaft, and eastwards from the Sea Wall Shaft. After repairs to the large pump at 5 miles 4 chains, the headings here were clear of water on the 19th of October and the Marsh Shaft on the 23rd. Alexander Lambert arrived at Sudbrook on the 29th and descended into the Old Shaft wearing Fleuss' apparatus, but he had just returned from where he had successfully helped to raise the steamship Austral from Sydney harbour. Whether Lambert was feeling the strain from this voyage is not known, but he was unable to reach the headwall door. Next day he tried again but this time in his normal diver's dress, and assisted by two other diver's succeeded in closing the door.

By the 3rd of November, the pumps had entirely cleared the tunnel of water and the Great Spring was imprisoned yet again, but it was obvious to Walker that he required additional pumping power to deal with the Great Spring once and for all. After he made enquiries in the many mining areas throughout the country, two 70 inch and two 60 inch beam-engines were ordered from Harvey's of Hayle. The two 70 inch and one of the 60 inch engines would be installed over the Old Shaft at Sudbrook and all winding operations from here would be transferred to the New Shaft. The other 60 inch beam-engine would be erected at the 5 miles 4 chains Shaft as the closure of the headwall door under the Great Spring had produced a greater quantity of water at this shaft.

To feed these new engines with steam, ten Lancashire boilers were ordered of 7 feet in diameter and between 27 and 30 feet in length. This estimated expense of this additional plant was £16,000 at a time when Walker was already £100,000 out of pocket due to the unforeseen difficulties that he had encountered. As the installation of the engines together with the construction of the engine houses would take some considerable time, little progress could be made in the area of the Great Spring for some months.

In the meantime, progress in the other sections of the tunnel continued at such a rate that the supply of bricks could not keep up with the bricklayers lining the tunnel. At that time bricks were obtained from four sources; the Cattybrook Brickworks near Bristol ( a brickworks started Charles Richardson in 1864 ) at 100,000 bricks per month, two brickworks in Staffordshire at 500,000 bricks per month and the tunnel's own brick making plant at 5 miles 4 chains at 600,000 bricks per month. To keep up with the needs of the bricklayers, an additional one million bricks per month were secured from five different brickworks in Staffordshire, making a total of 2,200,000 bricks per month - sufficient to build 200 houses every month

Copyright © by John Daniel 2013