|

|

|

Oil - fired locomotives

Fuel availability became a major problem for home and industry in the latter stages of the Second  World War and was made much worse by the severe winter of 1947. On the Railways, coal had deteriorated in quality and risen in price. In 1939, average coal consumption was 44.21 pounds at 4.44d (1.85p) per mile whereas in 1944 this had risen to 55.18 pounds at 11.88d (4.95p) per mile. Part of this situation arose because Great Western engines ran best on coal from South Wales, but in the years of austerity after the war, this same coal was labelled by the government 'for export only', even coal produced from Great Western's own coalfields.

World War and was made much worse by the severe winter of 1947. On the Railways, coal had deteriorated in quality and risen in price. In 1939, average coal consumption was 44.21 pounds at 4.44d (1.85p) per mile whereas in 1944 this had risen to 55.18 pounds at 11.88d (4.95p) per mile. Part of this situation arose because Great Western engines ran best on coal from South Wales, but in the years of austerity after the war, this same coal was labelled by the government 'for export only', even coal produced from Great Western's own coalfields.

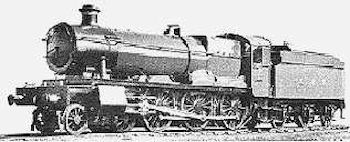

Because of their difficulties, the Great Western began a programme of converting engines to run on oil fuel. The Anglo - Iranian Oil Company assisted Swindon Works in the conversion firstly on heavy freight 2-8-0s, followed later by five 'Castle' locomotives, numbers 100A1, 5039, 5079, 5083 and 5091.

The scheme was sufficiently promising to prompt the government to sponsor a large scale programme to convert some 1200 engines in all railway companies to help overcome the coal shortages. By 1948 when the railways had been nationalised, a total of 93 engines had been altered, including 36 on the Great Western, but the government realised that they had insufficient foreign exchange to pay for the additional costs of oil fuel, estimated to be £300,000 per year, and with this in mind, all locomotives were switched back to coal within nine months.

Best steam coal had a calorific value of some 14,000 BTU's whereas with the oil fuel as used by the Great Western a calorific value of 18,000 was available.

The various advantages of oil-burning could be summarised as follows. Firstly, ease of control, in that the best coal-burning fireman could hardly help waste by blowing-off steam on his engine on occasion, whereas it was gross carelessness when this happened with an oil-burner. Secondly, the gradual clogging of the fire on a coal-burner did not occur; the fire was always clean, moreover there was no dust or dirt produced. With oil, the footplate was always clean whilst if any tender-first running was necessary the difference was most marked. There were various other advantages not least that the fireman on an oil-burner could give more assistance to his driver in looking out for signals, etc, whilst on the road - nor did the driver get distracted by the glare from the firehole door when working in the hours of darkness.

Copyright © by John Daniel 2013.